Slot Die Coating Perovskite

Slot-die coating is a metered coating process. 208 Slot-Die Coated MAPbI 3 Perovskite Solar Cells by Optimal DMSO-Content and Age of 2-ME Based Precursor Inks Jinzhao Li Janardan Dagar Oleksandra Shargaieva Marion A.

Roll To Roll Slot Die Coated P I N Perovskite Solar Cells Using Acetonitrile Based Single Step Perovskite Solvent System Sustainable Energy Fuels Rsc Publishing Doi 10 1039 D0se00460j

Incorporation into existent thin-film solar cells or.

Slot die coating perovskite. A uniform and high-quality perovskite film over large area is essential for high-performance PSMs. Organicinorganic hybrid perovskite solar cells PSCs are developing rapidly but most of the PSCs are prepared by spin coating process which is not compatible with potential large-scale high-throughput industrialization. Build slot-die coating solution for perovskite-silicon tandem photovoltaic cells.

The slot-die coating deposition of perovskite in an uncontrolled humid environment RH up to 70 following an accurate characterisation of the perovskite material is reported in this work. Using an additive and. However this potential depends greatly on the ability to deposit perovskite active layers using large scale deposition methods such as slot-die coating without sacrificing efficiency.

Conduct modeling and reliability studies to optimize the system. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators. To make perovskite solar cells an industrially relevant technology large area deposition techniques are needed and one of the most promising is slot-die coating.

R2R deposition of the electron transport layer and perovskite is performed at ambient atmosphere from nontoxic solvents compatible with industrial manufacturing. Slot-die coating is a coating technique for the application of solution slurry or extruded thin films onto typically flat substrates such as glass metal paper fabric or plastic foils. Flatken Hans Köbler Markus Fenske Christof Schultz Bert Stegemann Justus Just Daniel M.

R2R deposition of the electron transport layer and. It has since become relevant in numerous commercial processes and nanomaterials related research fields. Various coating methods have been applied to deposit large-area MAPbI 3 FAPbI 3 or mixed cation andor anion perovskites including blade D-bar slot-die spray and ink-jet coating as well as.

By the addition of a templating polymeric agent it was possible to avoid the use of the toxic and hardly scalable antisolvent bath. This represents a remarkable achievement towards perovskite solar cell industrialization. To fabricate large-area PSCs various fabrication methods have been proposed including spray coating slot-die coating vacuum deposition and blade coating.

Perovskite solar cells are produced by R2R slot die coating on flexible substrates with a width of 30 cm and the web speed of 35 m min1. Scientists in Germany demonstrated a slot die coating process for large-scale production of perovskite thin-film solar cells that achieved a maximum efficiency of 2083. This new project starts on April 15 2020 and will end at around March 31 2022.

Using a perovs Perovskite solar cells. Theory Design and Applications. Perovskite based photovoltaic devices hold the promise to greatly reduce the cost of solar energy production.

Slot-die coating is a promising deposition technique with high precision and excellent material utilization which can accelerate the industrial-scale. Days devoted to the scaling-up of perovskite deposition by slot-die coating1516251724 or solution-based ink-jet2628 and gravure2930 printing techniques. This review article details the progress reported in the literature where slot-die coating has been used for the deposition of both the perovskite layer and other layers in.

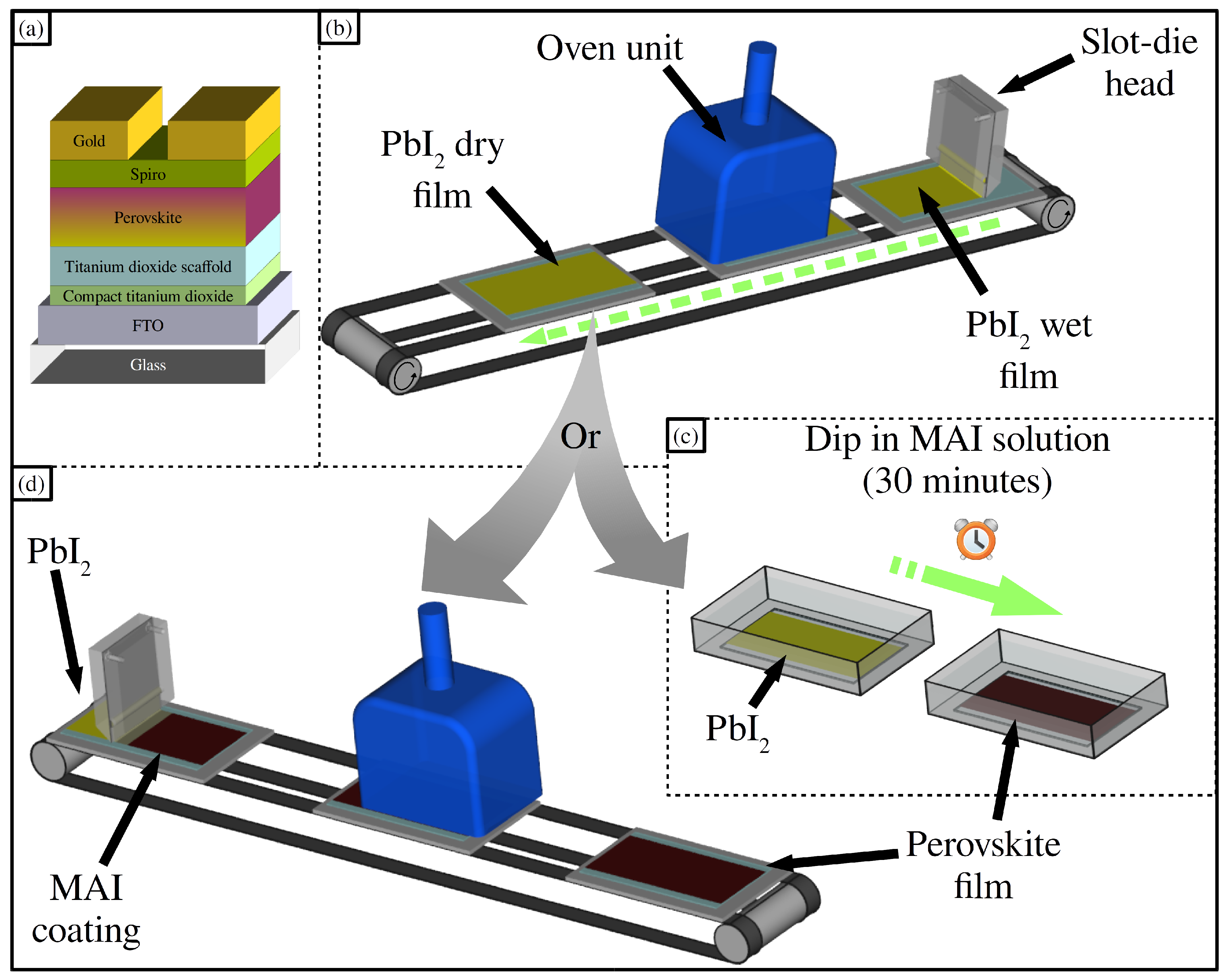

A range of alcohols are assessed as solvent for methylammonium iodide formulations for use in slot-die coating. With the optimized perovskite precursor solution of DMF-NMP solvents containing DPSO additive we slot-diecoated the FACs perovskite films on fluorine-doped tin oxide FTONiMgLiO substrate with the size of 20 cm by 14 cm movie S4. Although slot-die coating has repetitively been mentioned as a desirable production technique in recent papers 1 2 3 Solaronix is the first to demonstrate the slot-die coating of the entire monolithic perovskite solar cell structure.

The solvent system choice is found to be critical to achieving good coating quality conversion to the final perovskite and for the film morphology formed. The process was first developed for the industrial production of photographic papers in the 1950s. Slot-die coating large-area formamidinium-cesium perovskite film for efficient and stable parallel solar module Sci Adv.

Produce a hybrid perovskite slot-die deposition solution for large solar panels sized 600-1200 mm and beyond. However the device area of a PSC is one of the biggest challenges for the commercialize applications. All other parameters work to improve the uniformity and stability of the coating.

In their final device form perovskite solar cells can be produced in a variety of architectures by eg. Here the blade-coating technique progress for the PSC fabrication has been reviewed. Slot-die coating which is a coating process used for depositing thin and uniform films with limited material waste and low operational cost.

This means that the wet film thickness is determined by the amount of solution placed onto the substrate. CH3NH3PbI3-based planar perovskite solar cells were fabricated by slot-die coating a scalable method. An in-depth discussion of the slot-die technique can be found in Slot-Die Coating.

Perovskite solar cells are produced by R2R slot die coating on flexible substrates with a width of 30 cm and the web speed of 35 m min 1. Herein we focus on slot-die deposition as it allows a facile and scalable solution processing of several materials with good optoelectronic quality and in principle onto any. The importance of slot-die coating in perovskite PV Manufacturing methods and associated production costs play an essential role when assessing any technology for industrial viability.

Slot-die coating tends to produce perovskite. Többens Antonio Abate Rahim Munir and Eva Unger DOI.

Slot Die Coating And Pumping Of Perovskite Liquid Film Download Scientific Diagram

Fully Slot Die Coated Perovskite Solar Cells In Ambient Condition Springerlink

Blade Coating And Slot Die Coating A B Schematic Illustration Of Download Scientific Diagram

Slot Die Coated Planar Perovskite Solar Cells Via Blowing And Heating Assisted One Step Deposition Sciencedirect

Schematic Of Slot Die Coating And Positioning Of The Air Knife Download Scientific Diagram

Perovskite Layer Deposition Using Slot Die Coating Technique 73 Download Scientific Diagram

Scalable Slot Die Coating Of High Performance Perovskite Solar Cells Sustainable Energy Fuels X Mol

Scalable Slot Die Coating Of High Performance Perovskite Solar Cells Sustainable Energy Fuels Rsc Publishing Doi 10 1039 C8se00368h

21 8 Efficiency From Perovskite Solar Cell Made By Production Line Process

Solar Perovskite Production On A Roll Kaust Discovery

Amorphous Hole Transporting Layer In Slot Die Coated Perovskite Solar Cells Sciencedirect

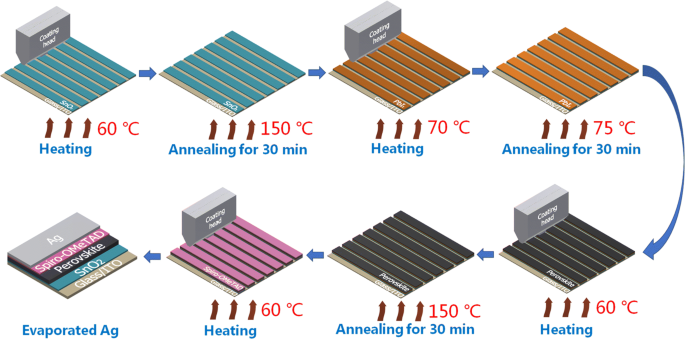

Materials Free Full Text Sequential Slot Die Deposition Of Perovskite Solar Cells Using Dimethylsulfoxide Lead Iodide Ink Html

Slot Die Coating Of Perovskite Solar Cells An Overview Sciencedirect

Posting Komentar untuk "Slot Die Coating Perovskite"